Commercial Partnership: ECOLIT

My name is Denis Lozenko and I am the founder of global construction company ECOLIT which has, for over 15 years, provided our unique proprietary patent pending light gauge steel and light weight foam concrete construction system to the construction industry.

During this time we have established a revolutionary solution for insulating a cold light steel frame which is proven by tests for over 100 years. I am pleased to present our technology to Ireland.

Thanks to modern legislation and care for the environment our system exceeds all building regulations in terms of energy efficiency and our Carbon output can be reduced by up to 70 per cent from normal concrete structures of the same nature while keeping proper comfort and sense of a fully fledged housing system for our customers.

Let me tell you a bit about our technology and future in Ireland.

Since we live in an era of a changing climate and resulting natural occurrences of destructive high winds, flooding and fires many people like to keep to proven traditional construction methods.

Our team has worked on a solution to provide a building system that is of solid monolithic in feel and of higher performance of traditional building methods but can be designed, manufactured and constructed as quickly as framing systems in Ireland.

This can all be done while using the local workforce and knowledge.

We started experimenting with pouring concrete into the body of the framing wall. Here we are faced with such a phenomenon as metal corrosion.

In a normal situation, zinc coating on steel protects it from corrosion, but prolonged contact with ordinary concrete constantly causes corrosion and, as a result, subsequent failure.

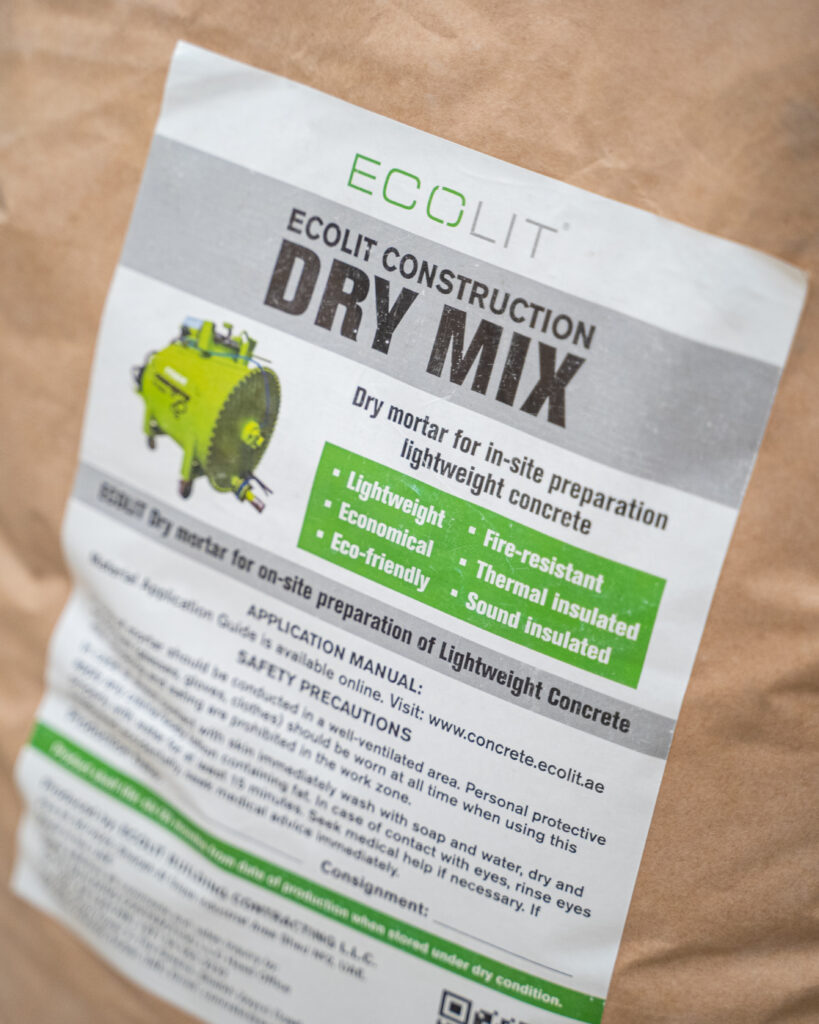

From our tests over the years, we eventually made an achievement of creating a modified foam concrete solution. This is our very eco-friendly dry mix that reduces its carbon footprint in use by up to 70 per cent.

So, it is the future of eco-friendly building systems. This dry mix is supplied from our factory and is mixed with only water directly on the construction site from our proprietary ECOLIT mobile machines.

Transparency and progress can easily be achieved and shown onsite to clients. After thoroughly mixing where the resulting mixture increases several times and is ready for use.

Our application of up to 3 m3 per hour by two men can easily be achieved in an application of 400 mm into the ECOLIT light gauge steel walls. It is let dry and then continued the following day until the wall plate is reached.

The result is our light gauge steel frame protected by our light weight foam concrete shell.

This both creates a thermal bridge free construction detail and a feeling of a solid monolithic or a concrete building but built as quickly as a panellised framing building system.

In this case the costs of the building are the same as with a framed building externally insulated with mineral wool, polyurethane and other insulation methods.

With our company of over 15 years of experience in this construction methods I can confidently showcase our systems advantages over other building systems.

ECOLIT light weight foam concrete is proven by tests and established projects as an eternal material not affected by time. It is an inert material and is found in abundance in the ground.

This characteristic has shown to be a highly proven system to fire resistance for buildings above three stories. It is also very moisture resistant. It is light weight yet extremely strong and will not move or settle as with other building methods.

I will also mention more of its main benefits to the end user.

- Micro climate efficiency. Does not ingress dampness, cold in the winter or heat in the summer

- High and accurate speed of construction and infill of walls and floors

- High sound absorbing walls and floors with a feeling of concrete

- Environmental friendliness – foam concrete does not emit toxic substances

- Ease of processing allows you to bring to life the most daring design decisions

- Efficiency – the cost of foam concrete is much lower than other technologies, but, in addition, thanks to its lightweight, it is possible to save on the foundation and on transportation

- The first degree of fire resistance

- Foam concrete goes well with any other material

- Our ECOLIT light weight foam concrete has a unique mixture which is been constantly improved

- Our ECOLIT technology is a patent pending system

If you are interested in our technology, then you can always contact me and I will tell you in detail all the nuances, as well as how you can become our partner and use foam concrete at your construction site.

Denis Lozenko

CEO and International Business Development

Phone: 0971585351788

Mark Farrelly

Business Development and Technical Director in Ireland

Phome: 00353877043057